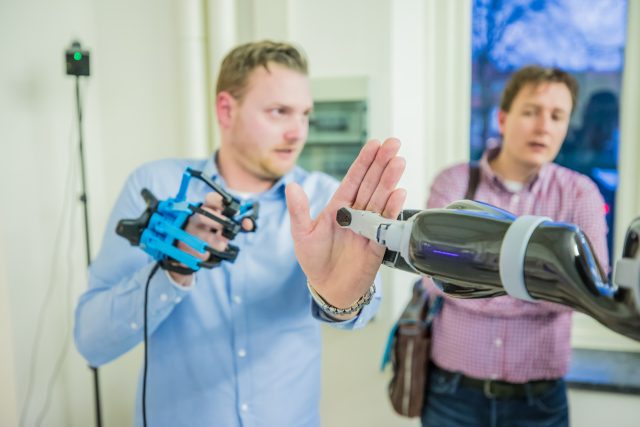

Work processes are very quickly becoming more efficient through humans and machines working together in much closer cooperation. The trend of the last couple of years is that besides monotonous tasks also complex tasks can be executed by robots. Traditionally robots are isolated and safe-guarded with fences. Now that robot work together with humans to a smaller or bigger extend, we call them cobots. The risks caused by this Human-Robot Collaboration (HRC) have to be addressed. How does that work? That’ s what you will learn during this training day!

From example, we learn that purely purchasing a robot made for HRC is not sufficient. In the training “Safe Human-Robot cooperation” all the applications of a safe cobot are discussed, such as: the CE marking, making a risk assessment and the validation of cobot applications. Besides that, the topics of the ISO 10218-2 norm and technical specification ISO/TR 15066 are discussed. This includes the different types of interaction, the four methods that can be used to safe guard the interaction between human and robots and the steps to get to a safe human robot cooperation.

Content

- Basics of robot safety from ISO 10218-2 and ISO/TS 15066 norms

- Execution of a risk assessment and risk reducing measures on cobots based on an example case

- Use and necessity of validation (both physical and calculating validity of safety systems)

- Basics of practical impact measurements based on the limit values of ISO/TS 15066

Target audience

- Technical personnel tasked with supervision of robot systems, machine designers and robot controllers

- Maintenance personnel

- HSE managers

- Engineering managers

- Project engineers in production environments

Prior knowledge

Knowledge about machine safety and process automation.

This course is organised in collaboration with PILZ.