The students follow an exciting programme that brings them into contact with all aspects of developing real robots. The students work in a multidisciplinary team to develop their own robot according to their own market and application research. During the programme, the student teams are based in RoboHouse.

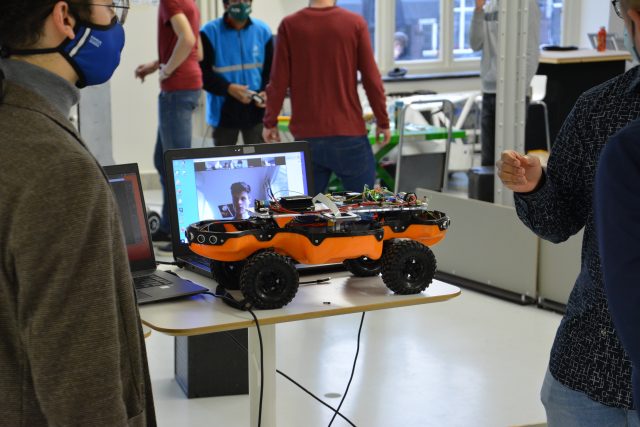

Demo Day

On 28 January 2021, the results of the minor robotics were shown during the Demo Day in RoboHouse. Because of the COVID-19 measures, not all members could be physically present. Nonetheless, thanks to a great organisation and the enthusiasm of the students, it was an inspiring (and safe) day.

Following we present the projects that the students of the 2020-2021 minor developed.

Team 1 Oxilia

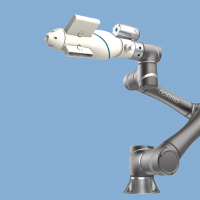

The TorsoDoc

Oxilia Prima can perform several simple medical tasks autonomously, resulting in a lower pressure on our healthcare system.

Using easy-to-change end-effectors on an TM5 700 robotic arm, the robot supports the work of nurses. It is entirely modular so it can be adapted to specific needs. The aim of our project is to reduce the workload of hospital staff, giving them more time for tasks that cannot yet be automated.

This project is commissioned by TorsoDoc.

Team 2 Crop Sentinel

Data collection robot for farming

Althea’s Crop Sentinel is a data collection robot for farming. It takes photos of crops in constant lighting conditions, made possible by a vision-box which is mounted on the back of the robot.

Most of the electronics, which include a custom PCB and an RTK-GPS module, are placed in the front part of the robot in a waterproof box. For an easy interaction with the user, the robot uses an LCD display and LEDS which indicate the status of the robot.

The machine is propelled by two hub motors placed on the front wheels with a high gear ratio which allows the robot to generate the high torque it needs. The robot can be monitored through a web app but can also move autonomously when needed. The positioning of the visionbox can be adjusted manually, as well as the distance between the wheel thus allowing the robot to work in different types of crop fields.

This project is commissioned by Odd.bot.

Team 3 Shiono

Scouting swarmbots

Shiono’s mission is to develop and build a swarm of sand cruising robots capable of detecting and mapping litter in Dutch beaches.

TechTichs believes in a future where robotic eco-systems support mankind and make a positive contribution by protecting our natural environment. We designed a tiny autonomous vehicle that can autonomously detect litter.

Individually, this would take a lot of time but by connecting multiple robots they can collectively map an area, like our own beaches! This is possible because our swarm can drive effortlessly on sand maneuver safely to avoid collision with humans, other robots or random objects.

This project is commissioned by TechTics.

Team 4 Delivery Fellow

Cratemate

We developed an autonomous robot that supports grocery-delivery by carrying heavy loads. Cratemate can follow you and lift crates to ensure a safer and more pleasurable work experience.

On average, a delivery driver supplies up to 800-1000 kg of groceries daily. The driver has to carry them all from the delivery truck to the homes of the customers. Therefore, this job is very physically demanding and often leads to injuries. To help these drivers, Team ARMS developed CRATEMATE: a robot that is able to follow a person autonomously and carry over 100 kg of load. With this robot, the deliverers can focus more on the social side of their job and improve the service that they offer.

This project is commissioned by AIRLab Delft.

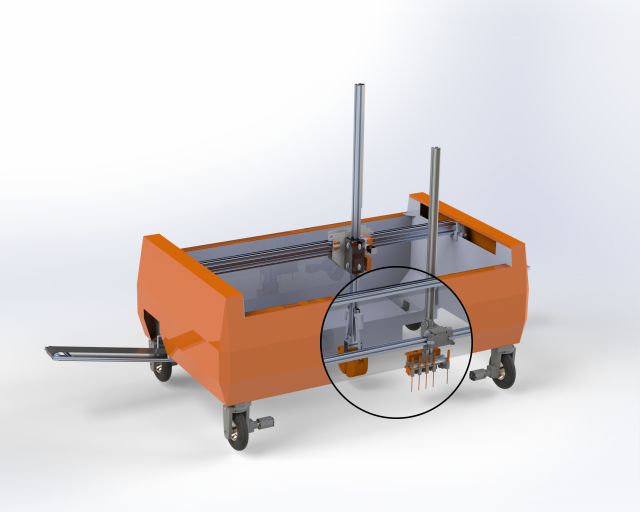

Team 5 DIRT

Cable excavating robot

The past few months, DIRT has engineered an automated digging machine to make it safer to adapt anything in the underground network of cables and pipes.

Alliander is responsible for maintaining the power grid in the Netherlands. As we are transitioning towards a more electric system, the grid must be enforced in many places. However, the people that are qualified to do this are scarce and workload is high, especially in urban areas where most work has to be done but the cables are also very concentrated. That is why DIRT has built a robot that digs out cables automatically and safely.

This project is commissioned by Alliander.

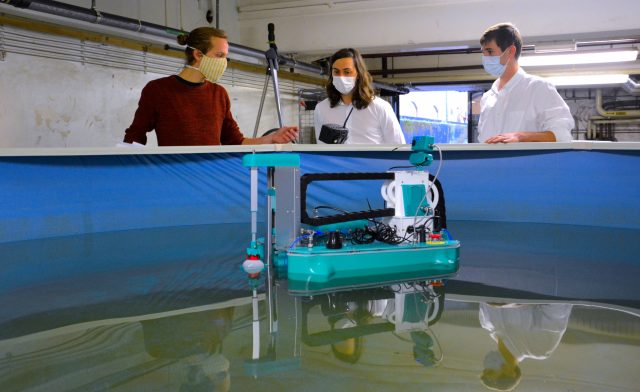

Team 6 Krill

Automated water sampling boat swarm

To improve the living ecosystem under the surface as well as above, it is important to monitor the quality of the water. That is why team Krill developed a boat that gains information by gathering samples.

All our robotic boats acquire certain samples on a sterile surface – but also up to half a meter deep – and directly measures these through sensors. These boats are a key in undertaking preventive actions when it comes to nutrition depletion or toxic waste in water streams. This will improve water quality in the Netherlands enormously.

This project is commissioned by Deltares.

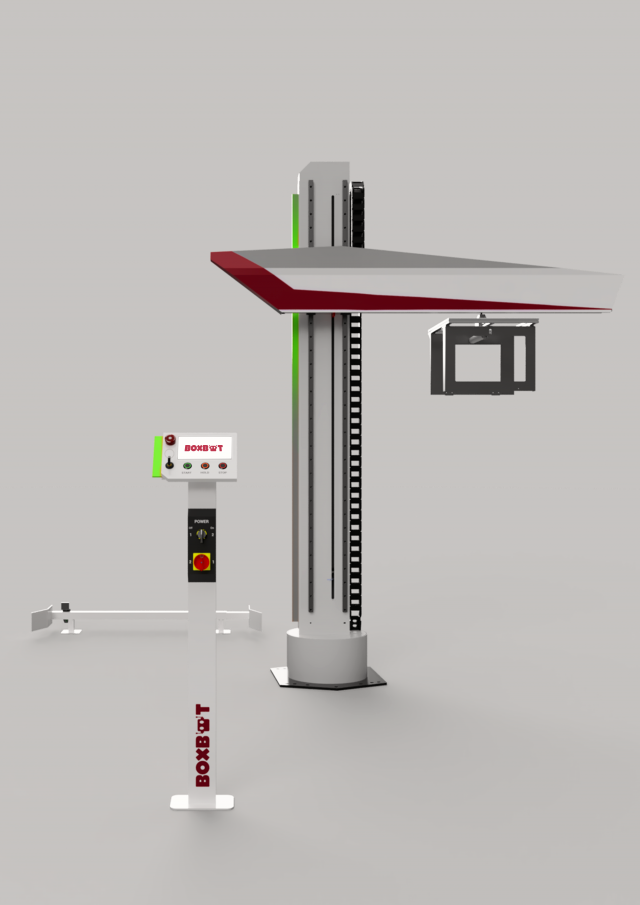

Team 7 BoxBot

Boxbot

In current manufacturing processes, almost everything is automated. But lifting stacks of cartons from a pallet to a packaging machine is still done by hand. Not anymore!

During our minor, we designed and developed a robot that can pick up a stack of cartons, move it to a conveyor belt and place the cartons the right way, fully autonomous. People working in the factory used to spend countless hours lifting and hurting their back, which could cause health issues. Now Boxbot takes over this task so employees can focus on the quality of the product instead.

Team 8 Bikebotics

Bike lifting and moving robot

After months of engineering, our robot will aid the employees of Accell in the assembly of electric bicycles by taking over the heavy lifting and moving of the bicycles.

Bikebotics had a difficult challenge: build a robot that supports the manual assembly of bikes. Taking over the entire process is not desirable, so we had to decide which part of the process would be most beneficial for Accell to use automation for. During our process we looked at image recognition, sensor framework, holding mechanisms and human-robot coproduction. Eventually we designed a robot that can easily lift and move electric bicycles to reduce physically intense work and increase safety and health on the workfloor.

See other projects that were made in RoboHouse

Back to overview

This project is commissioned by Accell.